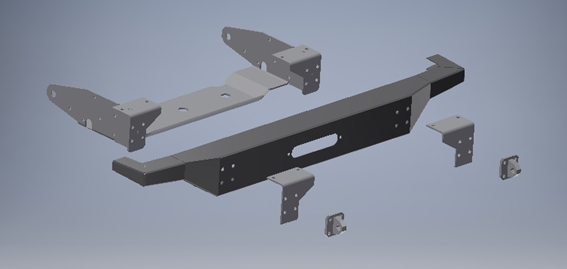

The base of a good bumper: its supports

27/01/2020

Welcome to the Rock Army blog. A space in which we will regularly publish our own articles related to the off-road world and especially, all those issues that concern us 4x4 users.

We invite you to follow this blog very closely, as we are going to delve into issues on which there is not much information. We know that you will find them interesting.

I'm Johnny Merino, founder of Rock Army, and since this is the first post of our blog, I see no better way to start than from the beginning. That is why today I want to talk about the foundations of a good bumper: its fastening system.

It seems surprising to think that, when choosing a metallic bumper for their All Terrain, many users ignore factors like these.

In fact, there are many factors that can intervene in the election of a bumper, depending on the needs of the use. The weight, the angles, the solidity, the functionality ... But there are some requirements that must always be met. One of them is a good fastening system.

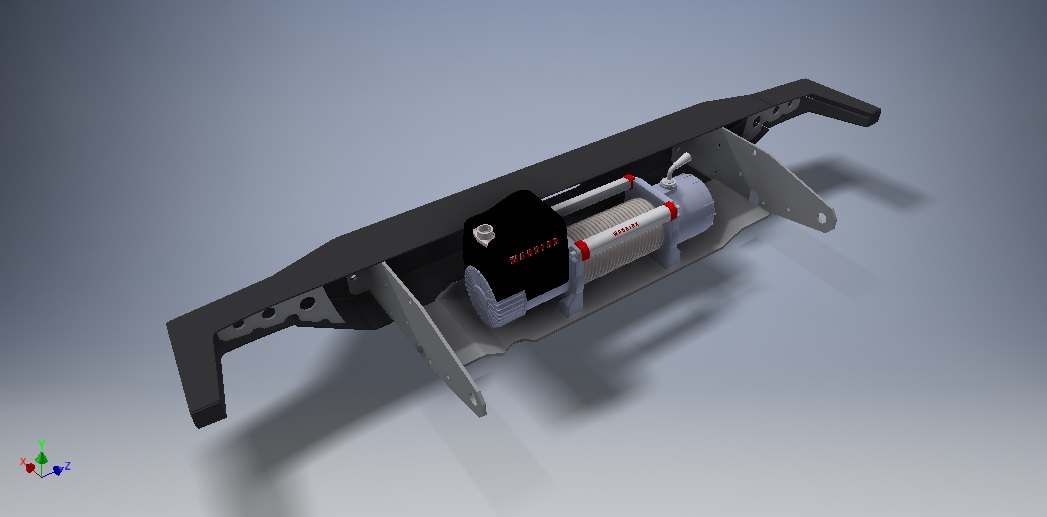

Every vehicle which is regularly used in the mountains, will at some point in its life, find itself in the situation of having to be towed or having to perform some self-rescue maneuver, unblocking of a partner or other type of work. For these functions, bumpers are a fundamental tool since they involve a robust structure in which we can install winches, shackle ports or attach other tools such as pulleys, ratchet jacks or manual hoists, among others.

In order a bumper can carry out all these tasks safely, it is essential that it has a fastening system and an anchor point design especially designed for these tasks. On the contrary, if the support is poor, it will not be a useful bumper. Let us bear in mind that a vehicle that weighs in empty 2.3T can offer a resistance which doubles its weight in certain situations. Let us take the example of a sunken vehicle in a thick barrel. The inefficiency of the wheels added to the windy effect that the mud can produce is able to increase the resistance of the vehicle greatly. But what happens if we also had to leave the immobilized vehicle, and when we return the next day we find that the mud has solidified? The path of a true All Terrain is a source of challenges, and that is why we must pay attention to its preparation, and be able to face them.

But let's get into the matter ...

What qualities must the bumper support hold to meet these situations?

First, it must be able to block the tensions derived from any five-way drag maneuver: ascending and descending, laterally and of course, forward (in a front bumper). For the tensions generated against the vehicle, a large section of additional requirements is opened since we would be talking about the behavior in the face of a collision, and on this task there is matter to invest two lives in analyzing and improving.

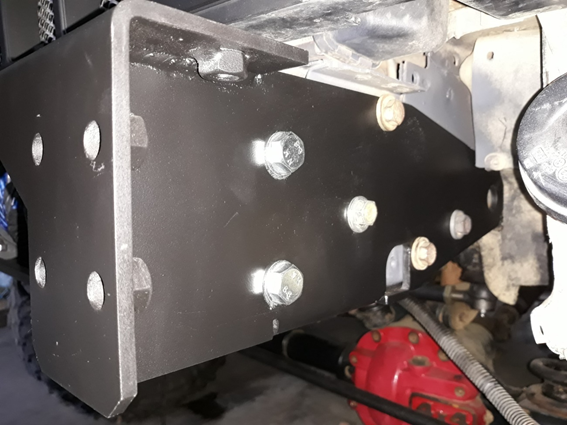

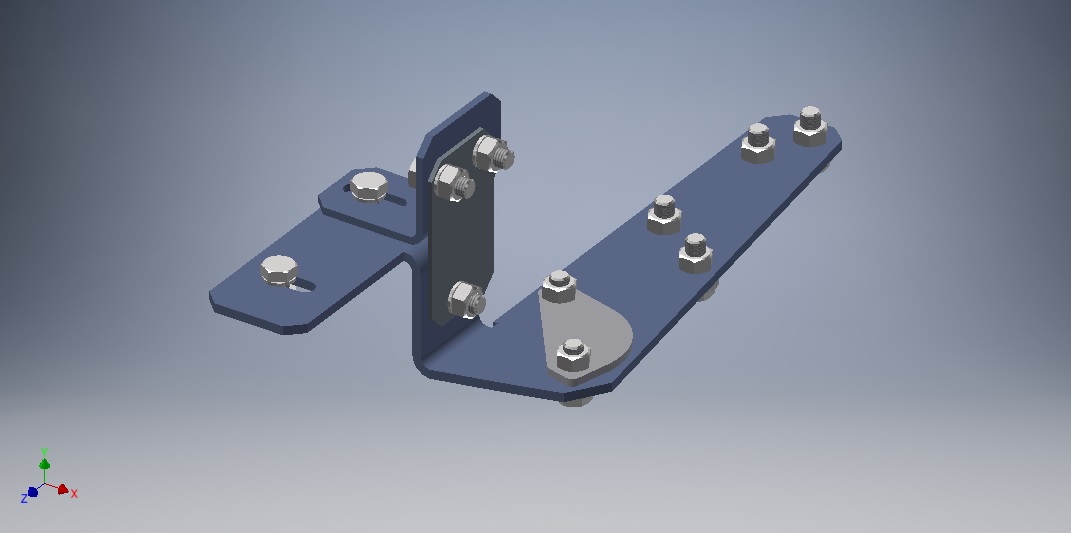

Another factor that must be taken into account when approving a good restraint system is the adequacy or adaptation to the structure of the vehicle. That is, it is not the same to integrate a bumper with winch in a vehicle that has a robust construction chassis and obvious anchors, than in a monocoque or a light chassis with a more complex structure. Depending on the solidity of the base, we will have more or less fastening points (screws) to dissipate the tensions in order to avoid deformations or tears in the structure of the vehicle. At the same time, the position, size and qualities of the screws must be in line with the tension that they are expected to withstand. In the following photo we see the support of one of our models for Jeep Cherokee XJ, with 6 transverse screws on each side of the monocoque stringers, three of which also hold the steering box on the left side. With this design, we do not only ensure a perfect support, but at the same time we reinforce the monocoque in the area of the steering box with the same support.

As a fact, a carbon steel screw in quality 8.8 and M12 is capable of supporting, according to theoretical data, 9.227 kg of tensile load (pulling it) and 7.382 kg of torsional load (before deforming). So, it could be said that a fastening of 4 screws M12 and 8.8 can theoretically support 36.900 kg as long as the materials on which they are fixed are able to withstand that tension. Anyway, this is a very generic orientation that will be more conditioned by the how than by the how much, since the design of the supports themselves is crucial for their effectiveness.

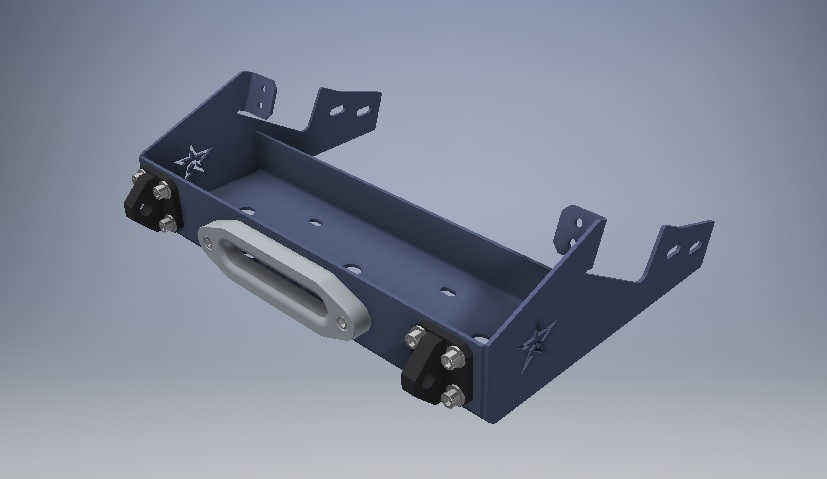

In the following photo we can see another of our monocoque supports with 6 vertical and three transverse M12 screws that embrace the monocoque stringer by its lower and inner side to block the fastening in the five senses that we mentioned at the beginning of the post. In addition, these supports have two interior sandwiches that reinforce the support and fix the whole together forming a block.

What more qualities should we expect from holding an off-road bumper?

Obviously, mooring points that are well thought-out.

Tying the sling is a daily gesture for many of us, but we rarely stop to think about the tension that runs through all the parts from the shackle to the structure of the vehicle. It is appropriate to intervene as few pieces as possible so that the tensions flow directly to the chassis, avoiding a path that generates lever effects or other torsions. Locating the mooring points directly on the supports is always a good idea, although sometimes, for design reasons, it is not possible, and other equally effective locations or systems must be sought. The important thing is that the system we use guarantees safety in the case of being subjected to extreme tensions. The pulls with the sling are something we should always avoid, but if necessary, the firmness of the mooring system must always be superior to the worst situation we can find. Be clear, a flying shackle is something nobody wants to see.

So, whatever use you give to your off-road vehicle, if you mount metal bumpers, look carefully at how the whole assembly will be subject (bumper + winch + carrier ) because when you depend on them, security must be on your side.